Machine Shop Services

TAM offers mechanical design precision machine shop services.

Mechanical Design

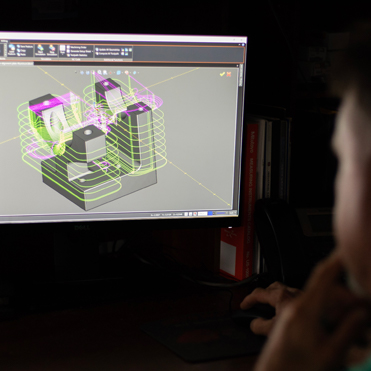

TAM offers a variety of mechanical design services, both to assist with automation and panel build services and general machine shop customers. Our engineers are capable of designing unique OEM solutions through all stages of the design, from initial concept to final assembly and commissioning. We are also capable of reproducing or designing custom parts and assemblies for use in most manufacturing environments. Our engineers use Solidworks 3D modeling software to create 3D models, 2D engineering drawings, and import and export most CAD formats. Solidworks modeling enables our engineers to examine parts using Structural Finite Element Analysis, and render basic motion animations to eliminate possible collision issues in complex designs.

Contact us for more information about our mechanical design services.

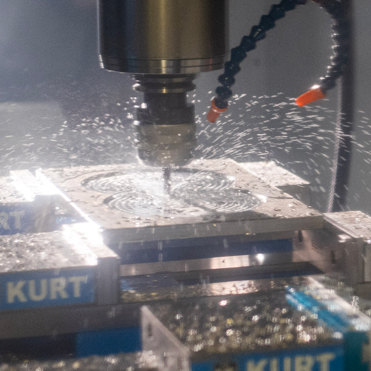

CNC Machining

TAM has 3,000 sq. ft. of climate controlled machine shop space adjacent to its 11,000 sq. ft. manufacturing facility in Woodlawn, VA. Our Machine Shop Manager Rod Bryant has over 30 years of experience in precision machining operations.

Capability

- HAAS®, Inc. TM 3P

- BOSS LS-3655 Laser Engraver

- OMAX® MAXIEM 1515 Water Jet Cutter 5’x5′ Capacity

- CNC system programming using Bob-CAD Software

Contact us for more information about our machine shop services.

Conventional Machining

Capability

- Acer E-Mill 40″ x 20″ x 16″

- Surface Grinding

- Starrett Optical Comparator

- Lathe — Victor 14″ x 40″

- Horizontal and Vertical Band Saws — Horizontal Saw Capacity is up to 10″ Round & Square Material

- Iron Worker (shearing, punching, bending)

- Welding (MIG up to 3/8″ steel and 3/8″ aluminum)

- Vibratory Finishing Process

Contact us for more information about our machine shop services.